A DCIM system is the central intelligence that ensures stability, security, and efficiency across your entire data center.

A DCIM (Data Center Infrastructure Management) system integrates software and monitoring tools to supervise the entire data center infrastructure, including IT equipment, power, UPS systems, cooling, and environmental sensors. Its strength lies in consolidating all this information into a single platform to enable precise operations and informed decision-making.

Real-time visibility allows issues to be detected before they become critical failures, improves operational efficiency, and optimizes resources. In an environment where seconds of downtime can represent significant losses, DCIM is not optional, it is essential.

Complete visibility

It monitors IT equipment, power, UPS systems, and cooling, centralizing critical information in a single dashboard.

Live data.

It provides real-time readings that allow anomalies to be detected and enable fast decisions based on accurate information.

Unified management

It integrates monitoring, alerts, configurations, and analytics into a single system that simplifies operations and reduces human error.

Operational efficiency

It enables optimization of energy consumption, improves cooling performance, and maintains stable conditions for critical infrastructure.

DCIM transforms complex metrics into clear actions that strengthen data center continuity

Beyond monitoring, a DCIM system allows deeper insight into the thermal, electrical, and environmental behavior of the data center. It can analyze how cooling units operate, verify the status of UPS and PDUs, review environmental sensors, and evaluate historical alarms to anticipate patterns and risks.

This predictive capability makes DCIM an indispensable tool for planning growth, preventing failures, improving energy efficiency, and operating with complete confidence.

DCIM Models

We offer versatile monitoring systems, from rack‑mount configurations to touchscreen options that adapt to compact and accessible spaces.

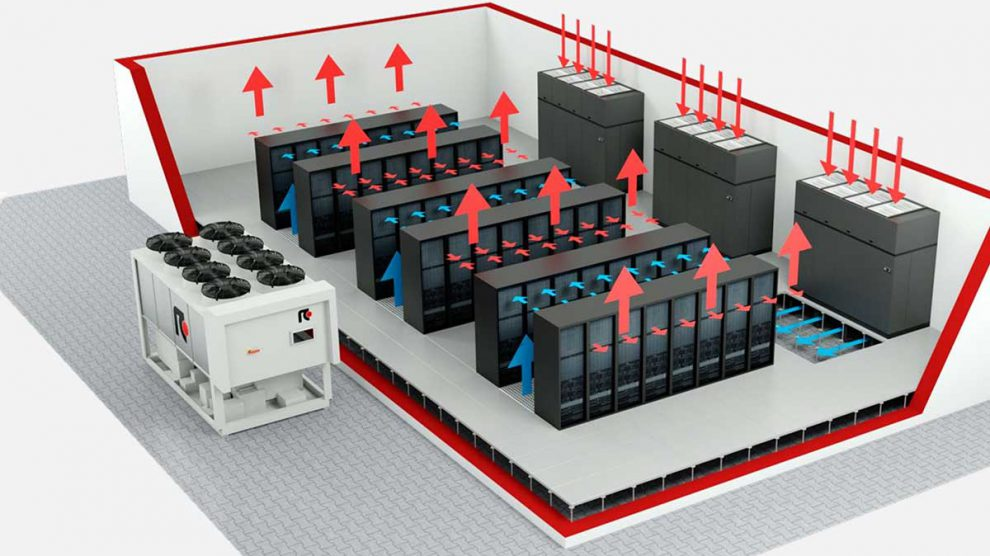

Air conditioning

It monitors supply and return temperatures, pressure levels, operating modes, and fans to ensure proper cooling.

Power and UPS

It monitors voltage, current, frequency, operating modes, and power distribution to prevent failures or critical imbalances.

Safe environment

It monitors temperature, humidity, smoke, water leak sensors, and door status, with alarms and historical logs.

Key Benefits of DCIM Monitoring

-

-

-

Centralized control

Centralizes monitoring of power, cooling, IT, and environmental systems, enabling fast and effective decisions in critical conditions.

-

Reduced risk

Detects potential failures before they impact operations, improving reliability and reducing downtime.

-

Energy optimization

Identifies inefficiencies and promotes adjustments that reduce electrical consumption and operating costs.

-

Higher availability

Ensures proper conditions for critical equipment through real-time alerts and trend-based analysis.

-

Secure planning

Facilitates capacity forecasting, infrastructure expansion, and change evaluation without putting operations at risk.

-

Intelligent operations

Transforms complex data into practical actions, enabling more efficient management and reliable predictive maintenance.

-

-

Frequently asked questions

Yes, significantly. DCIM measures energy consumption in real time, detects imbalances, identifies excessive loads, and shows how electrical equipment and cooling systems interact. With this information, decisions can be made to reduce operating costs, such as redistributing loads, implementing more efficient cooling strategies, or identifying underperforming HVAC units.

It also helps determine whether an expansion requires new cooling units or if the existing infrastructure can be optimized.

Yes. Modular data centers are fully compatible with DCIM, SCADA, or BMS software. They communicate using protocols such as SNMP or Modbus TCP, enabling unified monitoring of power, temperature, access, and performance.

This makes the modular data center an intelligent solution that adapts to the organization’s existing technology ecosystem.

DCIM systems are designed to connect with a wide range of devices and industry-standard protocols, including Modbus, SNMP, BACnet, RS485, environmental sensors, power meters, UPS systems, PDUs, security cameras, and HVAC systems. Integration can be direct or through gateways.

The key is that DCIM acts as an information hub, collecting data and standardizing it to present clear and actionable insights.

DCIM is a preventive tool. It detects anomalies before they become serious failures. It can alert on out-of-range temperatures, water leaks, UPS failures, PDU overloads, high humidity, or unauthorized access.

By consolidating all this information into a single dashboard, technical teams can respond quickly and prevent interruptions. This reduces the likelihood of downtime, protects expensive equipment, and ensures stability for critical applications.

A DCIM system turns a highly complex environment into a visual and intuitive platform. It supports technical staff by:

- Prioritizing alarms based on criticality.

- Providing dashboards with consolidated information.

- Enabling remote diagnostics.

- Simplifying audits and reporting.

- Saving time on manual data searches.

In addition, it supports teams with varying levels of experience: junior technicians can quickly understand the data center’s status, while experts can dive deeper into advanced analytics.

It depends on size and complexity, but typically between 30 and 90 days. The prefabricated structure and integrated systems (power, cooling, monitoring) allow for rapid installation. In larger projects, timelines may extend to up to 120 days if integration with external systems such as DCIM or BMS is required.

While they share some functions, DCIM goes far beyond a BMS (Building Management System) or a traditional IT monitoring system. A BMS focuses on building infrastructure such as central air conditioning, lighting, access control, and general systems. An IT monitoring system supervises servers, switches, storage, and networks.

DCIM combines both worlds: power, cooling, UPS systems, racks, sensors, IT equipment, alarms, and historical data. It provides a comprehensive, unified view rather than a fragmented one. In addition, it enables correlation between variables, for example temperature plus power consumption plus UPS status, something other systems cannot achieve.

The ability to store, review, and analyze historical data is one of DCIM’s most valuable capabilities. It enables identification of patterns, correlations, recurring alarms, and areas where operations can be optimized. For example:

- If certain cooling units operate more hours than others, load balancing can be adjusted.

- If a UPS shows fluctuations at specific times, the root cause can be investigated before a failure occurs.

- If humidity increases in a specific area, leaks, infiltration, or insufficient insulation can be detected.

These insights enable proactive decision-making rather than reactive responses.

DCIM makes it possible to visualize how infrastructure will behave under increased demand, IT changes, new rack installations, or thermal growth. This helps avoid incorrect investments and enables expansion planning without compromising stability. It also facilitates migrations, modernization efforts, and reconfiguration projects by showing both current and future environmental conditions.

For example, if a high-density cluster is planned, DCIM can indicate whether the cooling system will support it or if adjustments are required beforehand.

CFD analyzes physical conditions such as airflow, heat, and thermal behavior, while DCIM monitors and manages the infrastructure in real time.

Both complement each other: CFD optimizes the design, and DCIM validates day-to-day performance. Together, they form the foundation of an intelligent data center, especially when integrated with AI and predictive monitoring.

Return on investment is usually seen across several areas:

- Reduced downtime: every minute of interruption can cost thousands or even millions.

- Lower energy consumption: by optimizing HVAC and electrical systems.

- Longer equipment lifespan: operating under optimal conditions reduces wear and tear.

- Reduced labor hours: less need for manual supervision.

- Better planning: avoids unnecessary or oversized purchases.

ROI can be achieved very quickly, especially in medium and large data centers where efficiency and operational continuity directly impact financial and service outcomes.

A DCIM system is essential because it enables real-time monitoring, measurement, and management of all critical data center infrastructure, including power, UPS systems, cooling, servers, environmental sensors, and more.

Data center operations depend on multiple variables that constantly change, and DCIM consolidates this information to improve visibility, reduce risk, and support data-driven decision-making. In high-availability environments, where minutes of downtime can result in significant losses, DCIM is not a luxury but an indispensable strategic component.